Comprehensive Tahoe Instrument Cluster Repair Solutions: Expert Gauge Fixes

Comprehensive Tahoe Instrument Cluster Repair Solutions: Expert Gauge Fixes

Blog Article

Ultimate Source for Advanced Auto Instrument Collection Fixing Techniques

In the world of modern-day car maintenance, the ins and outs of tool collection fixing stand as a vital aspect of making certain the optimal performance of a car. By exploring the devices needed, common issues encountered, and step-by-step repair service methodologies, one can furnish themselves with the knowledge needed to navigate the intricate globe of automobile instrument cluster repair service with confidence and precision.

Importance of Advanced Tool Cluster Repair Work

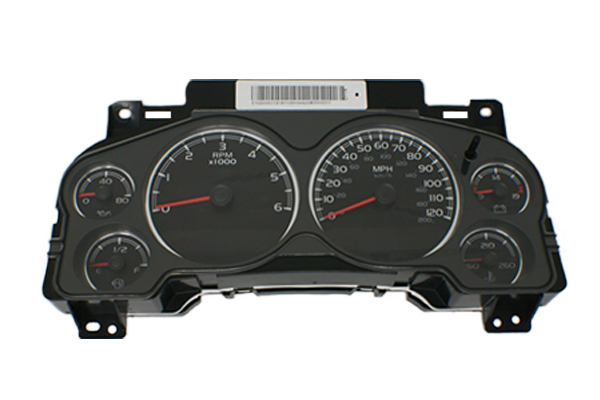

Understanding the value of sophisticated tool cluster fixing is essential for keeping the functionality and precision of modern vehicle systems. The tool cluster acts as the hub of details for motorists, displaying essential information such as rate, fuel levels, engine temperature, and cautioning indications. With the advancement of technology, instrument collections have advanced to incorporate complicated digital display screens and digital components, making repair work extra detailed and specialized.

Appropriate repair work and maintenance of the tool collection are important for making certain the safety and security and efficiency of the lorry. Concerns with the tool collection can bring about unreliable readings, breakdowns in vital systems, and security dangers when traveling. Advanced tool collection repair work techniques involve identifying electronic faults, altering sensors, and reprogramming software to recover optimum performance.

Devices and Equipment Required

To properly attend to the detailed fixing needs of contemporary lorry instrument collections, a specialized collection of devices and equipment is vital. A few of the key devices required for sophisticated auto instrument collection repair work include precision screwdrivers, trim elimination tools, soldering equipment, electronic multimeters, and diagnostic scanners. Accuracy screwdrivers are vital for disassembling the collection without creating damages. Trim elimination devices help in securely prying off bezels and panels. Soldering devices is needed for repairing broken connections or replacing elements. Digital multimeters are made use of to determine voltage, continuity, and resistance during diagnostic treatments. Diagnostic scanners are necessary for determining and troubleshooting electronic concerns within the tool cluster. In addition, having a good high quality blowpipe, desoldering pump, and solder wire is crucial for lugging out intricate soldering work. Correct illumination, a magnifying glass, and a tidy office are also vital for making sure precision and precision during repair work. By having these specialized devices and devices on hand, technicians can properly identify and resolve intricate issues in vehicle instrument collections.

Common Issues and Solutions

A number of usual issues frequently encountered in vehicle tool clusters can be successfully resolved through targeted services. One prevalent trouble is faulty evaluates, which may arise from a malfunctioning stepper electric motor. To address this, replacing the stepper motor can restore precise gauge readings. One more click to find out more common concern is flickering or dark lights on the instrument collection (tahoe instrument cluster repair). This can typically be credited to a damaged light find bulb or inadequate links. By changing the light bulb or making sure secure links, the lights concern can be conveniently treated. In addition, a malfunctioning odometer or display screen is a constant worry. This might be because of a defective display unit that requires to be changed to bring back appropriate performance. Recurring power or full failure of the instrument collection may stem from a blown fuse or electrical wiring concern. Monitoring and replacing the fuse, along with examining the wiring for any problems, can help resolve these power-related troubles efficiently. By identifying these common problems and applying the appropriate remedies, automobile instrument collection performance can be restored effectively.

Step-by-Step Repair Service Overview

A systematic technique to detecting and repairing vehicle instrument collection concerns is necessary for attaining effective and precise results. To begin the repair work procedure, the primary step is to thoroughly inspect the instrument cluster for any noticeable damages such as burnt-out bulbs, broken screens, or loosened links. Next, it is important to perform an analysis check using specific tools to recognize any type of underlying digital issues. When the trouble areas are identified, the fixing can begin by either changing defective elements, fixing harmed wiring, or rectifying sensing units.

Tips for Preventive Upkeep

After performing a detailed analysis check and finishing required repairs on the automobile instrument cluster, executing normal preventative upkeep measures is critical to ensure long-term performance and optimal performance of the lorry's necessary assesses and indicators. To start, it is vital to frequently evaluate the tool cluster for any indicators of wear, such as fading screens or malfunctioning lights.

Furthermore, upgrading the software of the tool cluster when necessary can ensure compatibility with any brand-new attributes or systems in the vehicle. It is likewise advisable to adhere to the maker's recommended maintenance timetable and standards for the instrument collection to preserve its long life. By integrating these preventative upkeep suggestions right into your routine automobile treatment, you can help expand the lifespan and dependability of your automobile instrument collection.

Final Thought

To conclude, sophisticated automobile tool collection repair service techniques are important for maintaining the functionality of contemporary vehicles. By using the proper devices and devices, addressing typical issues, and following a step-by-step fixing guide, technicians can effectively take care of and identify tool collection troubles. Applying preventative upkeep approaches can help lengthen the life-span of the instrument collection and stop future concerns from arising.

By checking out the devices needed, common troubles experienced, and step-by-step fixing methods, one can equip themselves with the expertise needed to browse the elaborate world of auto instrument collection repair with confidence and accuracy.

A systematic method to fixing and identifying automobile instrument cluster concerns is necessary for attaining accurate and reliable results. By following this detailed guide meticulously, auto service technicians can properly repair and detect tool collection concerns with accuracy and Continued self-confidence.

In final thought, sophisticated car tool cluster repair work methods are important for preserving the functionality of modern-day lorries. By using the proper devices and devices, attending to common concerns, and complying with a step-by-step repair guide, specialists can successfully detect and deal with tool collection troubles.

Report this page